Predictive maintenance involves using time-based data from in-service assets such as trains and planes to predict maintenance needs in advance. A key objective of this approach is the ability to correctly predict the right moment to repair or replace a part. If done too far in advance, the benefits of longer usage are lost; if done too late, unexpected failures can result, reducing asset availability. Thus, improving the accuracy of component lifetime predictions is an ongoing goal.

Cutting-edge tools for delivering such predictions include machine learning-based methods. Machine learning is a form of artificial intelligence, in which computers learn to detect complex patterns by analyzing large data sets. Although the basic framework and principles were developed decades ago, the data volumes and computing power that could make machine learning a reality did not exist until recently.

GETTING MORE FROM DATA

Machine learning is becoming a driving force in the field of industry-grade predictions, delivering significantly more reliable forecasts than traditional statistical methods, particularly where there is access to vast quantities of “unstructured” data (i.e., data that is not organized in a predefined manner). And as digitalization transforms end-to-end business models, the application of advanced analytical methods like machine learning are no longer just “good to have” – they will soon be business critical.

For more than a decade, rail and aerospace have been using “preventative” maintenance, which involves simpler analytical solutions that don’t endeavor to predict failures – instead erring on the side of caution by replacing parts systematically, often using equipment sensor data as a baseline indicator of system health. Predictive machine learning models, on the other hand, can make use of information embedded in previously untapped data sources and account for complex underlying relationships. As a result, these models can help identify failure patterns in components that would otherwise be difficult to detect.

As an example, we partnered with a North American railroad to use machine learning to predict the reliability of specific railcar components. Within weeks, the team was able to train a model that could predict certain component failures up to 40 days in advance, with an accuracy of up to 78 percent. Further, machine learning tools could potentially capture some of the niche technical and empirical knowledge of experienced maintenance engineers. Such expertise could then be preserved and deployed across the wider organization.

Early applications of machine learning in predictive maintenance have resulted in benefits such as better availability and reliability of assets, reduced capital expenditure (fleet size can be decreased with improved asset availability), and reduced operational expense (for maintenance hours, parts, etc.). Some of our clients have estimated that enhanced predictive maintenance could save them 20 percent or more on maintenance costs for key systems.

FROM CONCEPT TO REALITY

A fast development pace, achievements in other sectors such as retail and banking, and a growing amount of accessible data make machine learning an attractive technology for transport operators. To reap its full benefits, however, operators must understand what is different about machine learning development projects and what it takes to make them successful.

First, having large amounts of data available isn’t enough. Training a machine learning model requires defining all of the factors that could influence equipment behavior. This can only be achieved through collaboration between data scientists and experienced field engineers, with the willingness to understand each other’s culture and mindset.

Second, data must be captured and “cleaned” to focus on those factors that specifically influence equipment behavior, such as operating conditions, temperature exposure, and prior repairs. Data does not have be perfect, however; we have found that readily available data can be used to start training a machine learning model and increase prediction accuracy (while cleaning continues in the background).

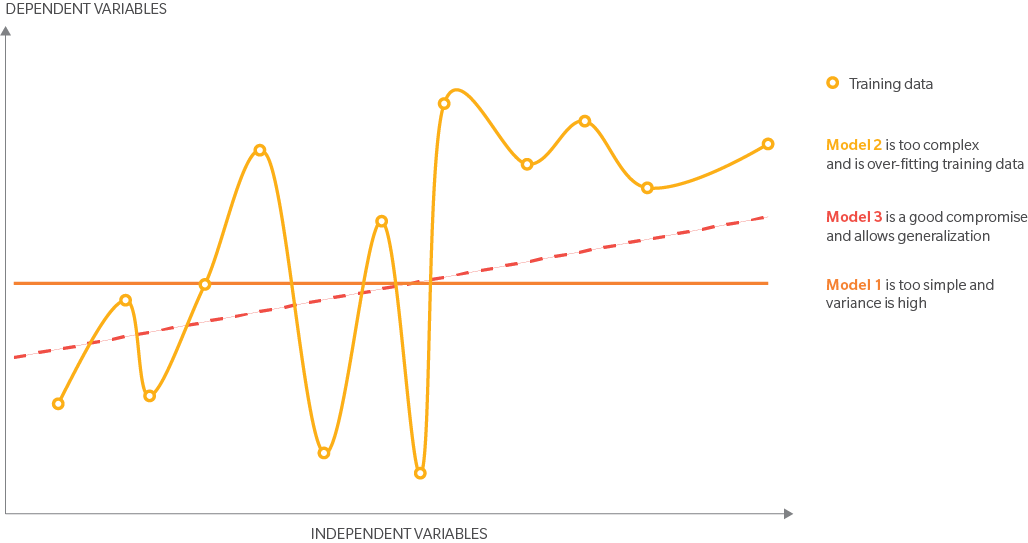

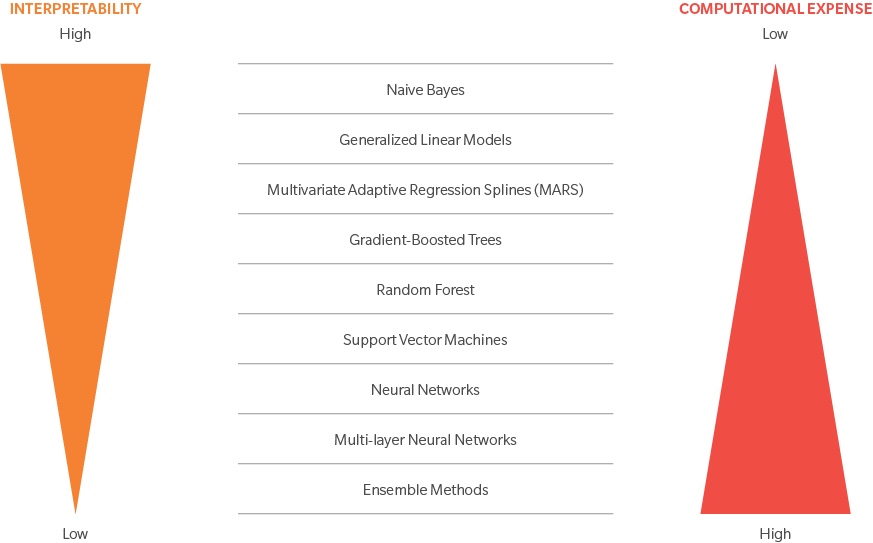

Finally, the right machine learning model for the job must be selected and trained. As models become more powerful, they also become harder to interpret. So, a simple “linear” machine learning model will deliver outputs that are easier for field engineers to use (if not quite as accurate), while complex “neural networks” will deliver more accuracy – but the models themselves are more difficult to understand.

ENGAGING IN A MACHINE LEARNING PROGRAM

The AGILE methodology, a well-tested approach for delivering machine learning projects, can help organizations realize tangible results in a reasonable timeframe. This approach involves initial iterations on a limited scope of equipment; the program is then progressively expanded as a company develops its capabilities. Early results can be used to obtain buy-in across the company and support the integration of machine learning tools across the business. To build initial momentum and enable knowledge transfer, operators might also consider collaborating with partners that have been actively developing machine learning and data science applications.

Machine learning is a promising approach for improving predictive maintenance and is certainly the wave of the future. It’s time for the transport sector to consider active engagement with this technology so that it can start to realize its transformative power.