Global supply chains in the modern business world still lack transparency. Moreover, managers often experience long delays in reporting cycles. This is no wonder considering supply chains often span multiple manufacturing and logistics entities with several tiers of suppliers. Furthermore, data is typically collected and stored in silos. Therefore, supply chain managers are prevented from gaining a clear and holistic view on crucial KPIs such as service levels and costs. As a result, information about real-time performance of end-to-end supply chains is often unknown and – if at all – reported only on a weekly, monthly or even quarterly basis.

As a result, business performance is often impacted directly. For example, plummeting delivery performance of critical part suppliers may become transparent too late resulting in sky-rocketing production lead times. Similarly, the malfunction of remote equipment may remain undetected or preventive measures might be taken too late resulting in exploding supply chain costs and lead times.

New technologies like the Industrial Internet of Things help to increase transparency. Remote data is collected via sensors and then forwarded to the cloud in real-time. But in a world where every entity in the supply chain defines its own performance metrics, this additional gain in transparency cannot be fully leveraged. Consequently, overarching performance optimization becomes impossible.

The ever-increasing complexity by collecting more and more data becomes apparent when zooming in on the driving factors of supply-chain data growth:

- Scope increases as vertical integration is abandoned in favor of outsourcing and specialization, with each partner taking a very tiny piece of manufacturing/fulfillment process— as well as logistic providers / brokers / wholesalers in between. This results in multi-echelon, intertwined supply chains around the world with an increasing number of countries, suppliers, and customers generating pieces of data.

- Scale increases with structured or unstructured data from each partner (forecasts, CRM transactions, transport optimization), semi-structured data (delivery times, RFID, GPS), and unstructured data sources (such as social media, weather forecast, call center logs).

- Data volume increases at each step: master data (product, customer, supplier); process data - e.g. from IoT devices (temperature, transportation route, waiting times); and finance data (invoicing, payment transactions). Add prefessionalized data analytics such as Machine Learning (modeling, optimization, prediction) and the depth increases even further.

- Finally, data dynamics are changing, as real-time data is available - GPS for route optimization, live and direct customer feedback either company initiated (NPS) or customer initiated (social media). In addition, data life cycles are shortening.

Consistent Data Access

Given such a chaotic stew of data, how can you make decisions based on data to improve supply-chain performance metrics on cost, service, and quality? How do you get consistent data for the end-to-end supply chain? How do you leverage relevant data across the whole supply chain? And how do you do this in an agile, real-time fashion?

To measure progress against your strategic goals, the data you need may be hidden along the supply chain or may not be measured at all. For example, if one of your strategic goals is high quality delivery service, you will need data from other players in the supply chain as well to measure overall delivery performance. You need to pull together data from different sources (e.g. enterprise, cloud, IoT, third parties and others) in real time on one platform for a clear view of the end-to-end supply chain.

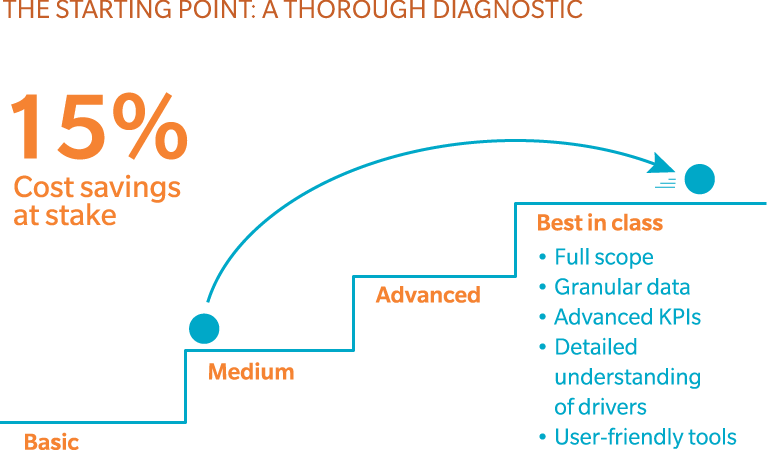

The solution in such cases is the implementation of a ‘data virtualization platform’. Simply put, this platform enables you to get the data you need, when you need it, for the way you want to use it. Industry examples are showing massive financial impact with more than 15 percent savings potential of end-to-end supply chain cost.

Real-world Example

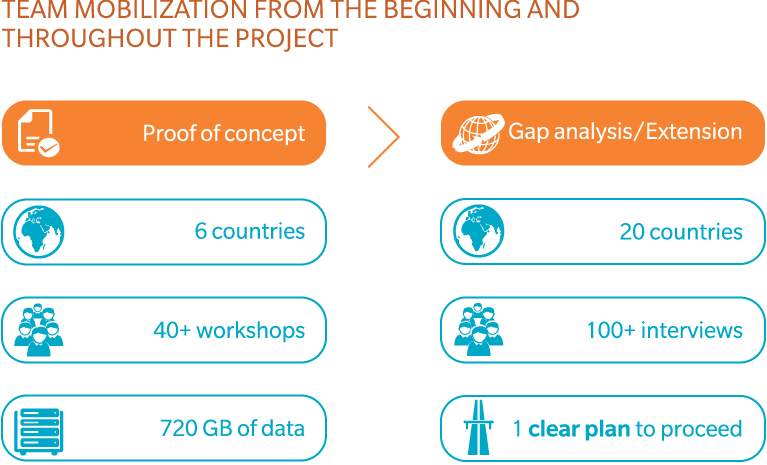

A leading supply chain solutions company that offers a range of services from design through manufacturing to logistics, integrating multiple vendors across facilities on a global scale was facing the challenge to coordinate its 200 manufacturing centers, 40 distribution centers with ~300,000 employees (users). Many of these users needed quick access to real-time information from various sources to make supply chain management decisions regarding trends, inventory, yields and shipments. By leveraging data virtualization, data sources could be accessed via analytics dashboards on mobile devices enabling quick decision making and improved productivity across the supply chain. Real-time details about trends, inventory, yields and shipments became available at the users’ fingertips.

A 3-Step Solution

To leverage these benefits, the road to supply-chain transparency requires a 3-step process.

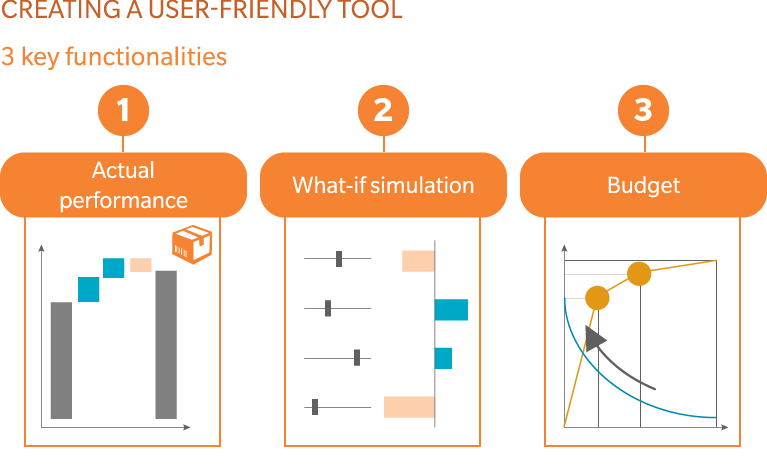

- Design an end-to-end supply-chain dashboard that fully aligns with your strategic objectives and enables end-to-end-transparency. Your strategy and business model will determine the KPIs and their target values. They should be customer-oriented—focusing on service, cost, and quality.

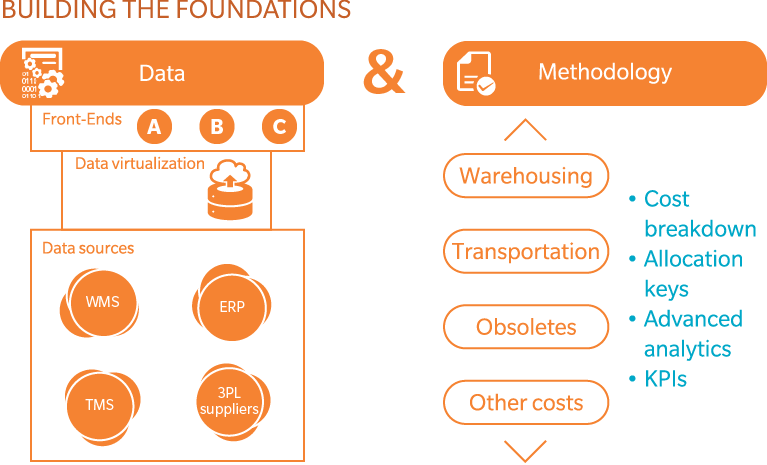

- Identify and connect data sources using a data virtualization tool. Data virtualization allows quick and easy integration of structured, semi structured, and unstructured data—in all formats (RDBM, data warehouse, big data, cloud, social media, newsfeeds, Excel or PDF files, …). The data arrives in real-time through a standard interface. A single-view portal allows connect to enterprise applications/ BI and analysis tools. State-of-the-art data virtualization solutions allow searching massive databases with more than 100 million rows in milliseconds vs. > 10 minutes in classical database systems.

- Adjust processes and organizational structure. With the strategy defined, the KPIs set up, and information made available, redefine the supply-chain processes (planning) and organizational structure (decision power) to actually exploit opportunities and align decisions along the supply chain.

This 3-step solution integrates the necessary data on one platform – allowing you to make better and faster decisions based on data tied to your strategic objectives. In the same manner, we have helped various clients across industries to significantly reduce their supply chain costs while improving service levels and quality.