Supply chains for B2B distributors do not offer such an interactive customer-centric interface because they are not sufficiently digitized yet. Yes, you may get a tracking number, but you have to visit a clunky web site to enter a long number, then learn that delivery will come in five to seven days, which is not particularly useful information. The overall end-to-end process of delivering goods in a B2B context – such as spare parts, construction materials, or any other supplies – is decidedly not customer-friendly, at least not the way Amazon has defined it.

Luckily, this shortcoming presents an opportunity because a supply chain offering transparency and convenience can be a real differentiator for customers. After all, the products themselves are rarely differentiated in distribution business models. The only way to differentiate is to offer a better service – and delivery of goods really is the only way to do that.

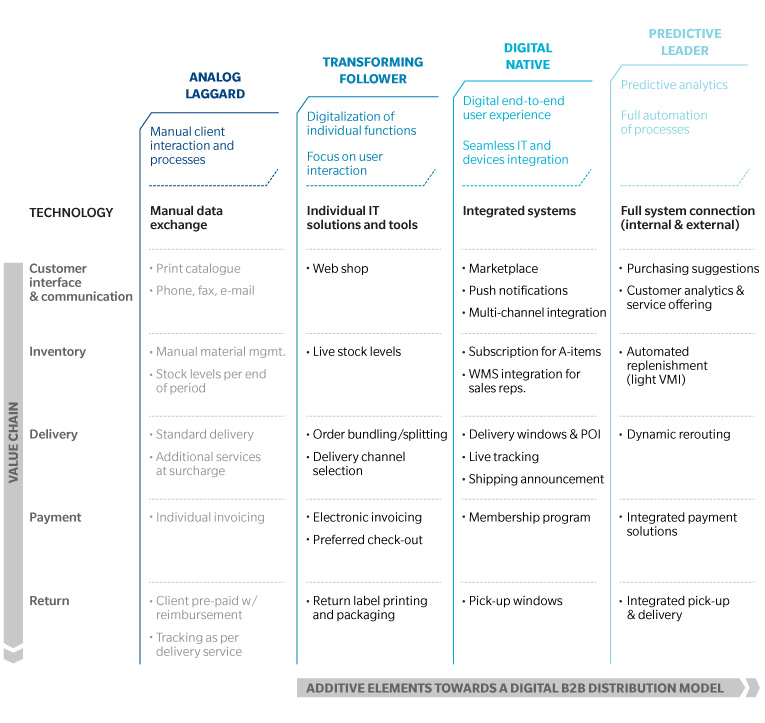

Exhibit 1: Ideas For A Digital B2B Distribution Model

Making supply chains digital and interactive presents several challenges. Since few executives see the supply chain as a potential differentiator – they rather see it as a fulfillment or distribution arm – the first step is persuading the CEO and COO that there is unrealized value in the supply chain. Second, supply-chain managers, typically out of sight, often tucked into a dark corner of a warehouse, must be integrated with other functions in the company. Only by integrating and learning how the outside world perceives their distribution of goods can supply-chain managers develop customer-centric thinking. Supply-chain managers need to be horizontally integrated with sales to understand customers, with procurement to understand suppliers, and with logistics to understand the actual shipping process. Finally, the supply chain must be digitized – not in a big bang way, but in an app-development way: fast, agile, iterative with “updates” every now and then (see Add Digital to Your Supply Chain—and Add Value).

The right approach to differentiation through digitization and interactivity is to define use cases (starting with one product or one set of customers), pilot quickly, and continue development in agile (one- to two-week) sprints. Start with simple tracking and improve the app over time. Add features such as push notifications to track goods in transit and allow delays. Eventually, you could offer some version of Amazon Prime, offering free shipping for an annual fee. If you break out each element of the supply chain’s value chain, there are specific additive elements that can transform your B2B distribution system from a laggard to a follower to a leader (see Exhibit 1: Ideas For A Digital B2B Distribution Model).

Providing a customer-centric supply chain also requires internal improvements. Customers may never see any of these efforts, such as improved demand forecasting, but they will intuitively appreciate them. Understanding demand improves a company’s economics by allowing just-in-time delivery and, because you refresh stock according to projections, can help to win new customers or increase share of wallet with existing customers – just as Amazon has proven it with its Prime program where the average Prime customer spends 4.6x per year what non-Prime customer spends.