To maintain a competitive edge in a post-COVID world, chemical companies are experiencing significant changes in how they must operate. The cost of doing business is rapidly increasing, with interest rates in the United States rising from 0.07% to 5.33% in the last three years, and cash cycles growing longer due to unwanted inventory driven by unpredictable customer demand and uncertain raw material supply.

These external challenges are revealing internal gaps for chemical businesses when it comes to their analytical capabilities, decision support systems, and integrated business planning and execution. This is especially true for inventory management. As product portfolios expand and supply chains grow increasingly complex, if these internal gaps are not closed, every part of the business will be affected. The sales team will face difficult conversations with unhappy customers due to unreliable material availability; operations will struggle with frequent production interruptions due to raw material shortages; finance will be unable to justify increasing inventory cost and unexpected write-offs; and business intelligence will have to navigate through multiple systems to maintain a centralized real time visibility on inventory performance.

As a result, it will be challenging for businesses to sustain profitable growth, with organizations facing margin erosion and difficulty in meeting customer service requirements. The typical impact can range from 2 to 5% in margin loss, 15 to 30% in inventory excess, and 20 to 40% in customer service decline. It’s therefore essential that organizations address these issues now if they wish to survive – and thrive – during volatile times.

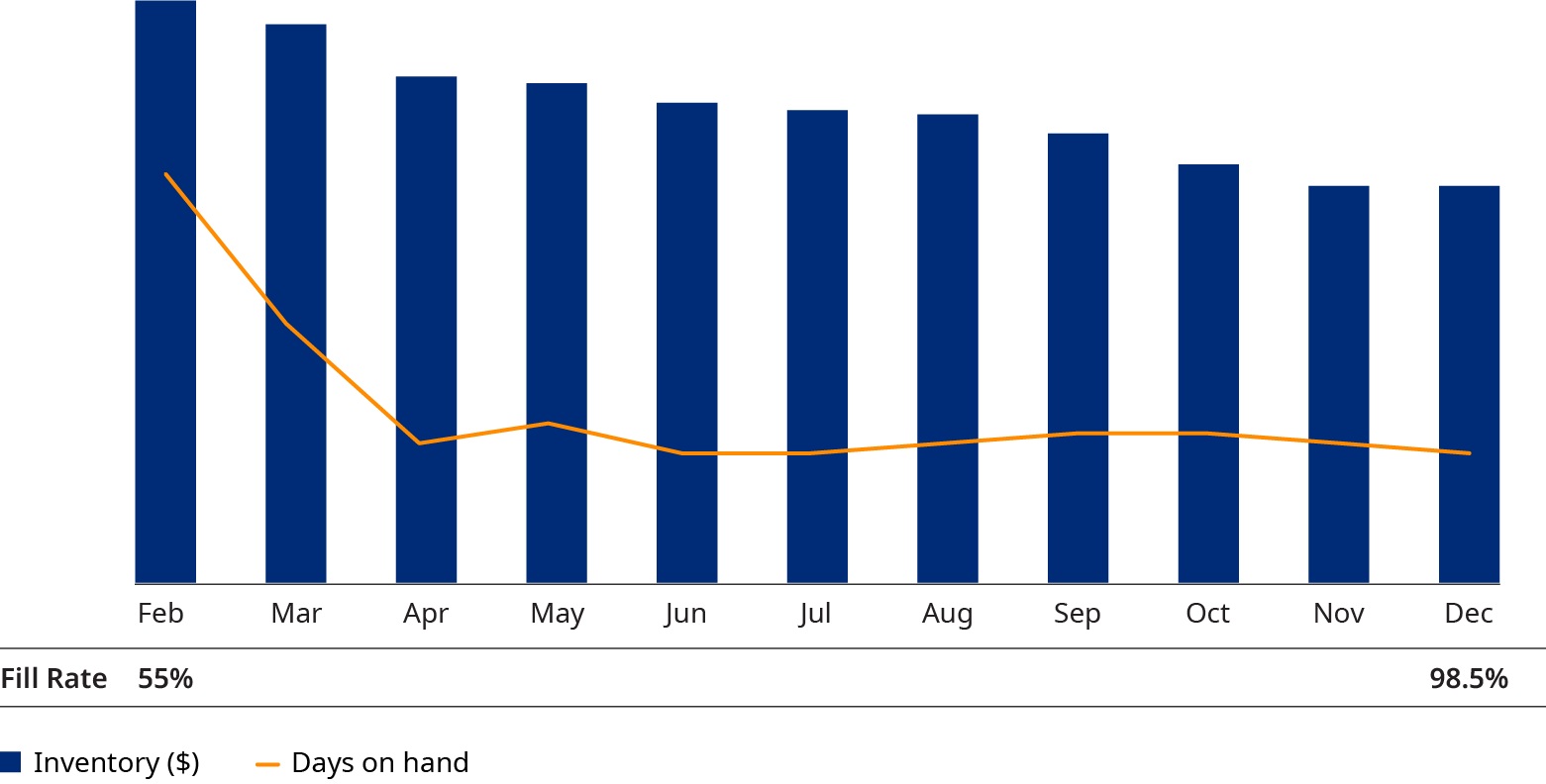

This is where dynamic inventory management comes in. We’ve seen this method help a specialty chemical manufacturer improve customer fill rates by more than 40%, reduce inventory by more than 25%, and reduce margin erosion associated with unplanned expedited freight movements and inventory write-offs.

How dynamic inventory management can help chemical businesses

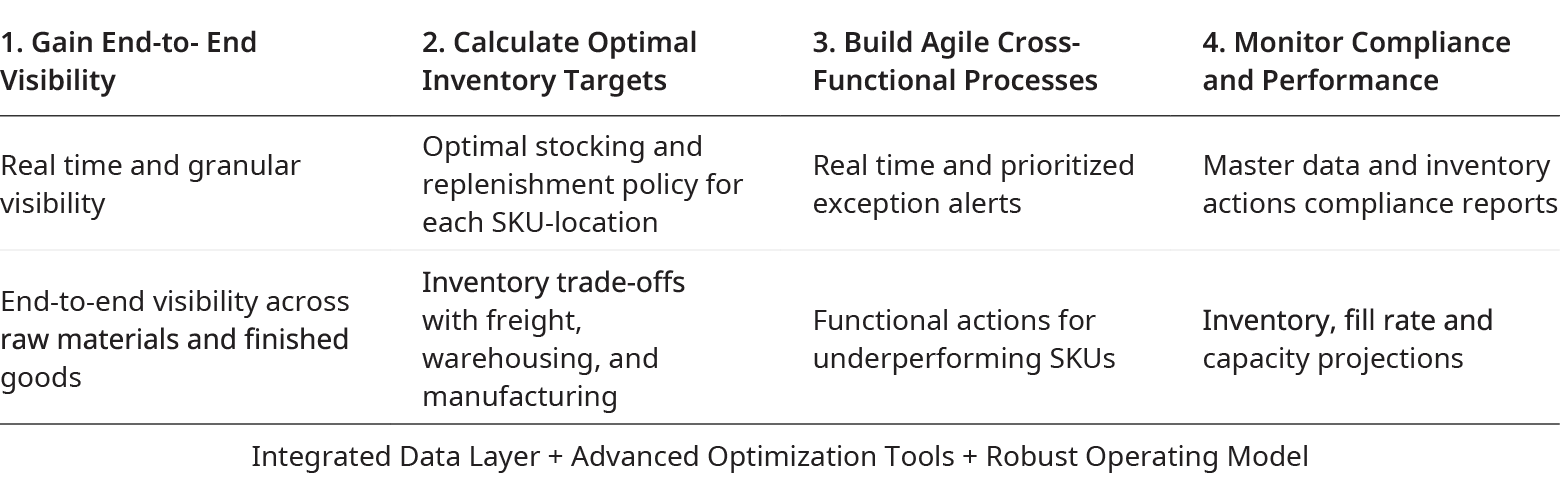

Dynamic inventory management involves a combination of visibility dashboards to highlight exceptions, optimization techniques to recommend best decisions, industry-specific processes to enable execution, and automated reports to ensure compliance. Used correctly, dynamic inventory management can help businesses in four key areas.

Gain end-to-end visibility

Accurate, granular, and timely visibility is the first step towards transformation. Gaining visibility helps businesses to understand historical trends, receive real-time status updates, and use this information to prepare for the future.

Typically, businesses struggle to maintain this integrated data layer. Some of the underlying issues can be inconsistent and stale master data; data decentralized and fragmented across multiple systems that lack integration; data not accessible at the required cadence; or the key performance indicators – both leading and lagging – are not accurately defined.

It is important to create an analytical data layer with a single source of truth that provides granular and real-time visibility on inventory and fill rate performance across the network.

Calculate optimal inventory targets

Calculating optimal inventory targets is a scientific exercise considering factors across the supply chain like demand and supply pattern, customer service targets, multi-echelon network structure and product flow path, bill of material, logistics requirements, warehouse storage and handling considerations, manufacturing setup and sourcing constraints. Beyond knowing the inventory targets, it is also important to translate those into system parameter settings that enable execution.

This is easier said than done; many organizations lack techno-functional skills to translate business requirements into corresponding system settings. Also, the optimal targets are not static, and they need to follow a cadence of refresh aligned to the demand and seasonality cycles. Targets must also be forward looking and informed by what is expected demand in the future and not so much on what happened in history.

Build agile cross-functional processes

Creating a path that will take the organization from its current state to the end goal of optimal inventory targets is an ongoing process that requires real-time and granular visibility on underperforming SKUs, recommended actions that each function in the organization can take, and a strong governance mechanism to ensure clarity around ownership of actions.

Imagine if there is a large planned production batch or purchase order placed with the supplier; and suddenly the organization loses that customer order. Failing to take timely action can result in years of excess inventory and eventual write-off. Such an exception requires an inventory planner, manufacturing scheduler, and material buyer to collaborate and identify immediate alternatives to avoid margin dilution. These are some of the many cases of organizations that are struggling to keep a check on inventory right-sizing and meeting customer service requirements.

Monitor compliance and performance

Today’s supply chain teams execute hundreds and thousands of actions every week. There is a need to enable automated action compliance tracking and drive continuous improvement. This allows the supply chain and product management to keep a watch on the health of their organization and take proactive and targeted measures. Also, it empowers them to tie incentives to role-specific key performance indicators. Lastly, the business needs the ability to view the projected inventory and fill rate performance and closely track how they are performing against that plan. As the organization gets in the rhythm of this new way of working, it not only improves business performance but also increases the efficiency and collaboration of the entire organization.

Ultimately, extreme volatility is here to stay, and businesses need to learn to be resilient and thrive in these changing times. Dynamic inventory management is one step in the right direction, and those who seize the opportunity soon will gain a competitive advantage.