Now the world is entering a fourth such revolution, which, in the words of the World Economic Forum, will be “characterized by a fusion of technologies that is blurring the lines between the physical, digital, and biological spheres.” Some of the boundary-crossing technologies of what is variously called “industry 4.0” or “digital industry” include cyber-physical systems, the Internet of Things, and new applications such as additive manufacturing (3D printing) and autonomous vehicles.

For rail and other transportation industries, the fourth industrial revolution promises continuing acceleration of innovation on both the supply and demand side. From the manufacture of rolling stock to how rail operators serve their customers, new technologies will lead to entirely new ways of doing business.

Disruption of value chains will reach unprecedented levels as well and will bubble up from the most agile and innovative sources in an interconnected world of “makers” as well as consumers rather than being driven by a few proprietary standard setters (e.g., Microsoft, Oracle). As an example, Deutsche Bahn has initiated a series of “Deutsche Bahn Goes 4.0” hackathons, in which anyone can participate to develop groundbreaking solutions to specific challenges, such as predicting track position defects or improving information desk services.

Digitizing Rail Supply

Digital industry will support new applications and business models for manufacturing and disrupt all phases of the supply chain. The product development process will become fully digitized, making it faster and more flexible. Railroads and their suppliers, working together, will be able to use real-time data, digital models, and virtual tooling and testing environments to reduce time and cost for the development of smarter and more sustainable trains. Standardization and modularization will be implementable even in complex environments. In addition, streaming data from rolling stock in operation will feed back to improve the design and build process, as well as enable better predictive maintenance.

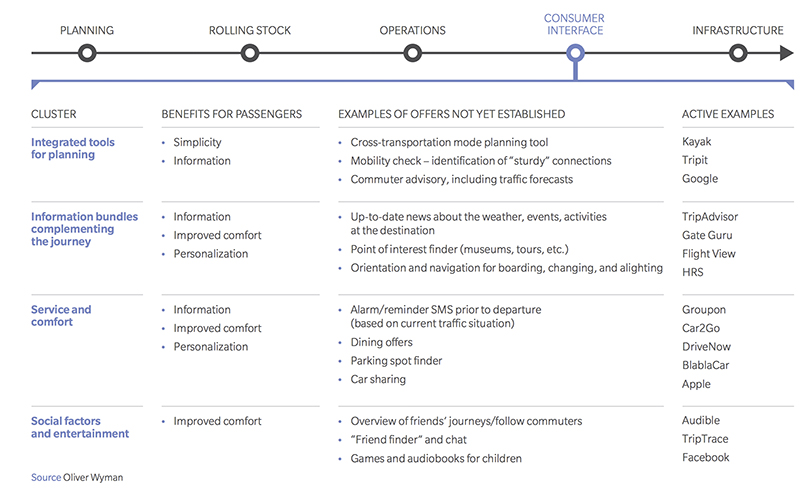

Digitalization Opportunities in the Passenger Rail Value Chain—Consumer Interface Example

Longer term, one might see rail suppliers become primarily product designers, outsourcing to “smart factories” that produce modular components—often 3D printed. While digital industry offers the potential for much greater customization, to take full advantage, the industry will need to work closely with certifying bodies and regulators to streamline currently complex approval and certification processes.

Smarter Operations and Interfaces

In the future, railroads also will leverage fourth-revolution technologies to improve operations.

For example, big data analytical techniques could increase train punctuality by better predicting and eliminating sources of service disruption. Smart planning and dispatching networks will significantly reduce system costs, as will trains that are autonomous or boast increased artificial intelligence. Robotization of intermodal terminals and yards might make use of technologies similar to those now in use at advanced ports, such as the Port of Hamburg.

Rail can be expected to play an important role in next-generation mobility, which will be increasingly characterized by a desire for access rather than ownership, technology-enabled transparency, two-way communication, and shared consumption.

On the freight side, products themselves will increasingly be direct users of the Internet; connected railcars and containers will provide their own streaming updates on location, condition, and itinerary. Longer term, autonomous cars and trucks will communicate directly with dispatch centers, terminals, and even trains, ensuring their passengers and cargos are at the right place at exactly the right time.

In passenger transport, digitization will improve ticket changing and pricing, and make access for customers easier. Most major rail companies are pushing mobile ticketing solutions; this will be especially good for customers if simpler or best-price fare systems are introduced in countries that now have complex tariff systems. (Ideally combined with automated passenger detection systems for coaches, so that separate ticket validation processes are unnecessary.)

Further improvements can be expected in customer feedback management. Current processes are extremely slow, inefficient, and not customer oriented. Through better use of social media and feedback platforms, rail operators will achieve real-time, streaming communication with their customers. Travelers will be able to immediately report train problems, and in turn operators will be able to fix defects faster and notify customers right away when problems are solved.

Running on Digital

Companies are already beginning to see incremental benefits from this fourth revolution. Long-term substantive benefits will be more challenging, requiring a new level of coordination between transportation suppliers and operators, and the willingness to embrace transformation that goes beyond information technology to the continuous revamping of organizational functions and activities as new game-changing innovations emerge.

Ultimately, the rules of business will be different, governed by a paradigm of being sharable, accessible, reliable, and able to perform at marginal cost. Companies will need to be both integrated and decentralized (“glocal”), and engage both their suppliers and customers more broadly and deeply. Railroads have a long history as networked businesses; the fourth industrial revolution will extend those networks in ways that we are only beginning

to comprehend.

This article was featured in BRINK.