This commentary first appeared in GreenBiz and Brink.

When automaker BMW invested in US clean steel startup Boston Metal, and Mercedes-Benz bought a stake in Swedish startup H2 Green Steel, the investments represented more than the greening of an industrial portfolio. They marked the first steps in the decarbonization of steel — a process that will require the reinvention of not only how steel is made but also a reimagining of the entire steel supply chain.

Because steel is a basic building block of the global economy, it factors into the production and operations of most industries, from auto production to aviation to construction to household appliances. That means it contributes to all of their carbon footprints. Although steel is one of the most recycled materials on the planet, its initial production and energy demands make it the largest industrial consumer of coal and one of the most carbon-intensive industries on Earth. The sector accounts for 2.6 gigatons of carbon dioxide emissions annually. Its emissions make up roughly 10% of the global total.

According to the International Energy Association, “to meet global energy and climate goals, emissions from the steel industry must fall by at least 50% by 2050, with continuing declines towards zero emissions after that.” To accomplish this, producers need a new energy source for production as well as new raw materials, requirements that will upend a large portion of the mining industry in particular.

Lowering Emissions in the Immediate Future

The steel industry will have no choice, as its largest consumers — companies such as Mercedes and BMW — increasingly demand “green steel” in their quest to meet their own climate targets. But steel producers won’t have to do it alone, as they begin to work together with their supply chains, both upstream and downstream.

Any solution will require a spectrum of technology changes and individual efforts to increase efficiencies that move the industry forward. In the immediate future, steel producers can lower emissions by 10% to 30% by applying the best available technologies and higher quality iron ores, and optimizing the fuel mix in blast furnace (BF) and blast oxygen furnace (BOF) operations. Efforts like these are particularly important in places such as China and India, where there is a preponderance of older facilities, and newer techniques and feedstocks can have a material impact on the entire industry’s emissions.

Bigger Investments are Needed for Sustainable Change

But realizing larger emissions reductions will require significant investment in new technology: This might include hydrogen-based reduction to produce DRI/HBI with low or no emissions, carbon capture, storage, and use technologies, or even newer alternatives, such as molten electrolysis. Also pivotal to progress will be an increased emphasis on the circular economy and recycling scrap steel to replace primary steel production.

Oliver Wyman modeled a range of global and key regional steel-producing scenarios, assuming ambitious combinations of technologies and emission-abatement measures. We also assumed changing market shares of BF-BOF and Electric Arc Furnace (EAF) based production. While exact timelines are hard to predict, certain trends emerged for the industry.

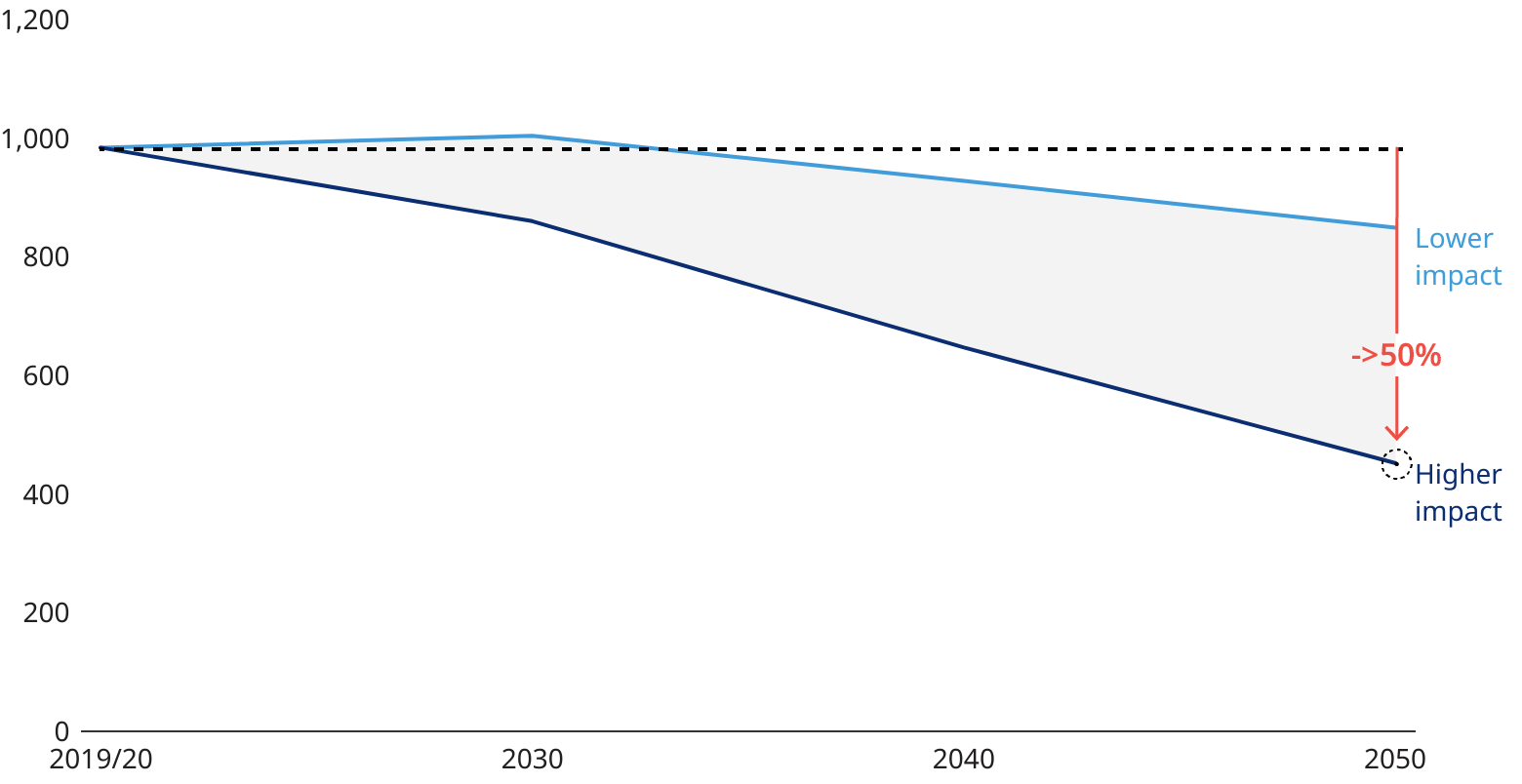

Ultimately, this overhaul of steel production will lead to a substantially reduced intake of metallurgical coal intake over time. By 2050, demand will drop to 50% of average levels in 2019 and 2020. While the decline will depend on how fast the largest customers deploy their efficiency measures, we think significant decreases will be possible in this decade.

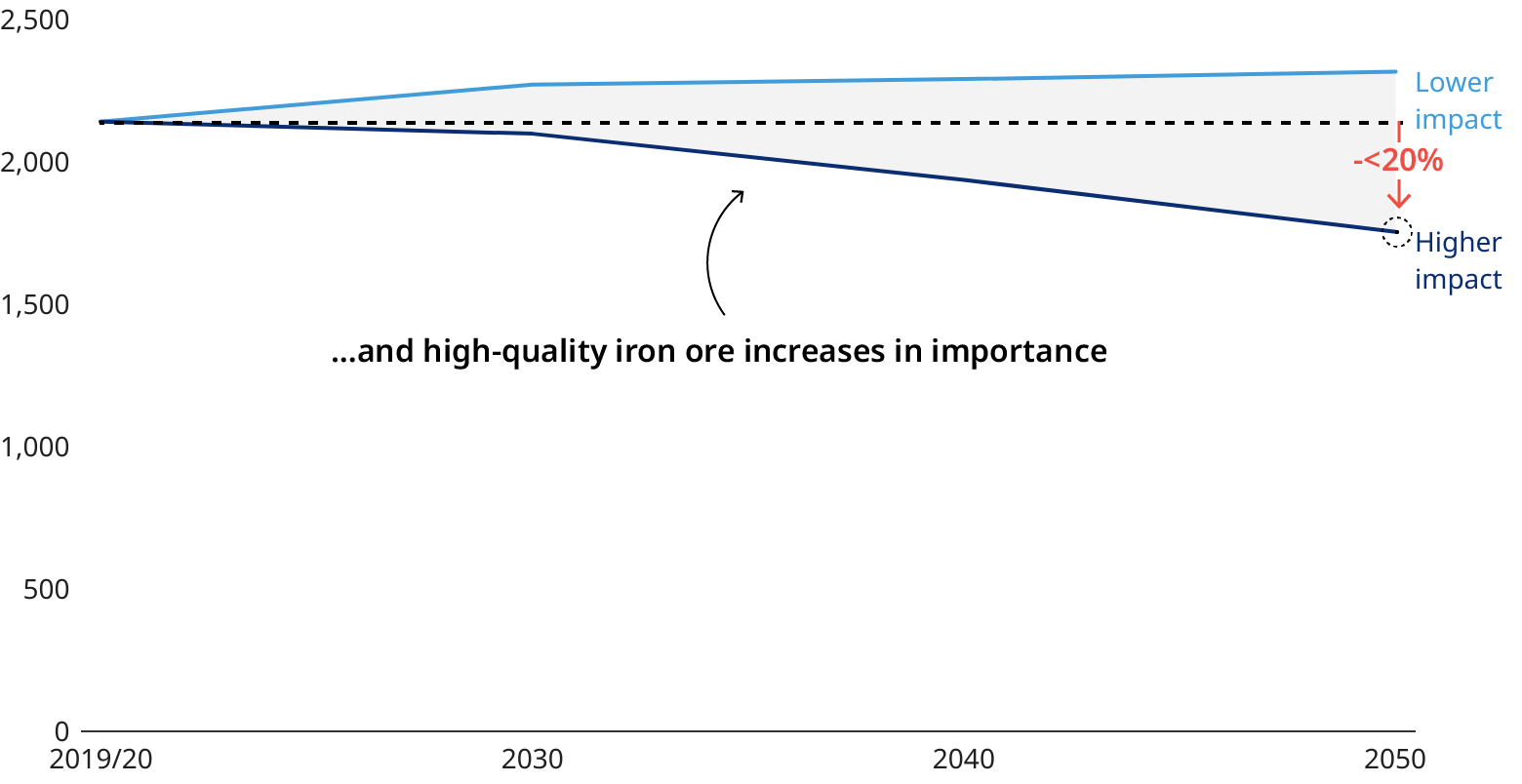

For iron ore, the outlook is more stable, but the composition of the supply will continue to change, as demand for higher-quality ores increases. These higher grades will play a key role in the realization of the first 10% to 30% of emissions reduction in BF-BOF operations, as well as for DRI/HBI production. Already today, the higher-grade ores are fetching significant price premiums.

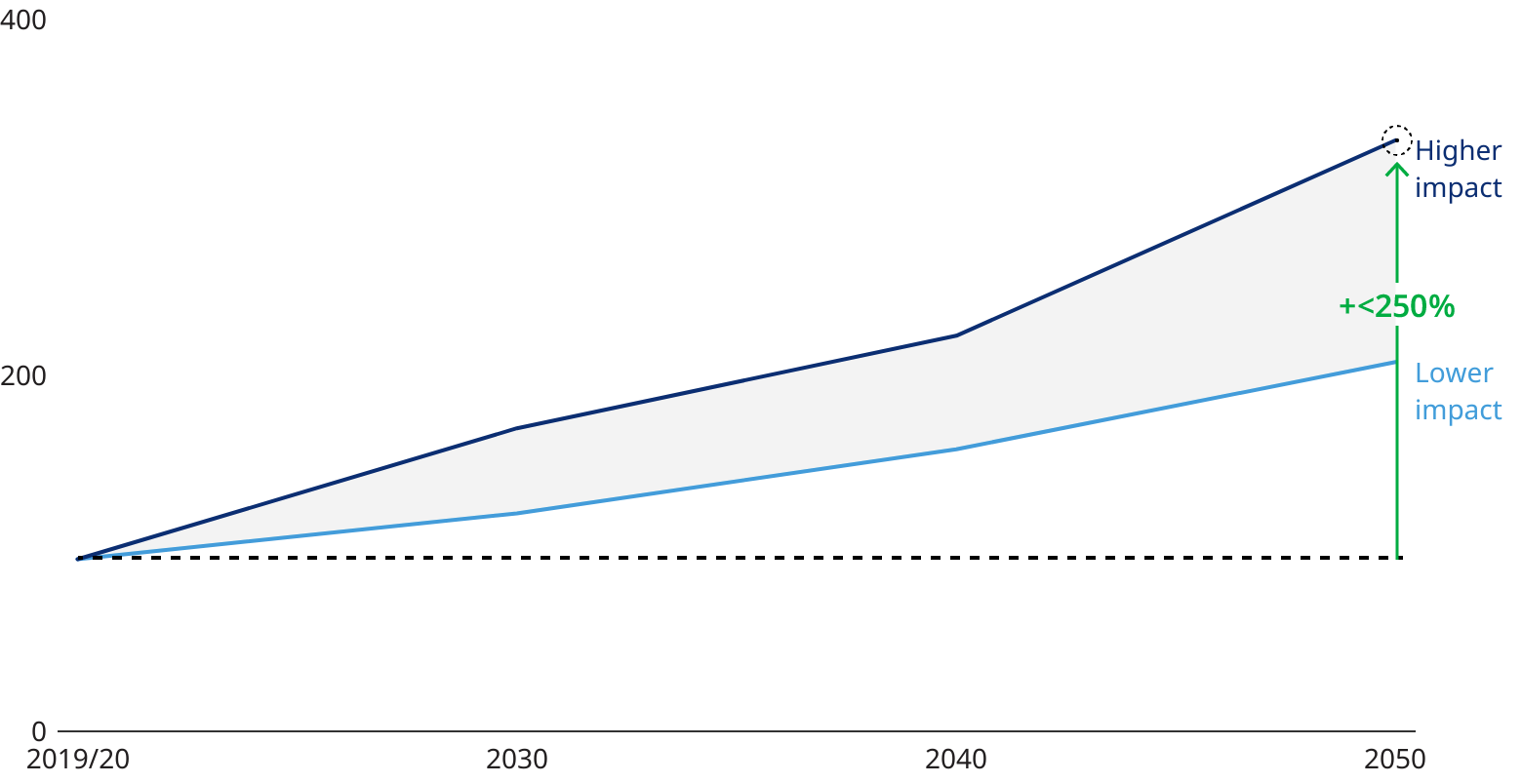

DRI/HBI-based steel will play an important role in the new steel industry. Even with supply limits on higher-grade iron ores, we forecast a significant demand increase for DRI/HBI through 2050 — maybe as much as 200% higher. This would also indicate a marked increase in the trading volume of HBI, suggesting the formation of a new commodity market.

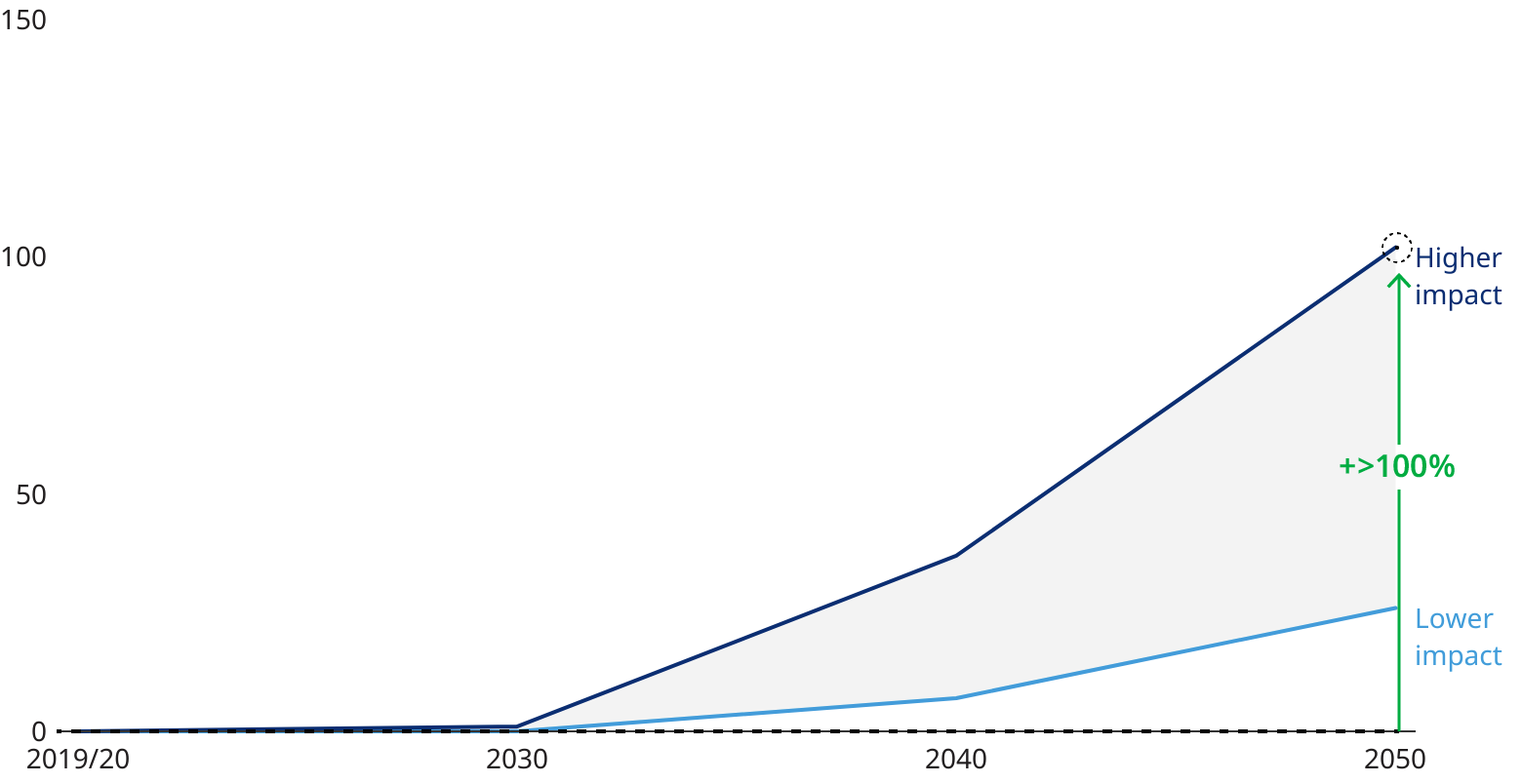

Increased use of DRI/HBI in turn will drive demand for hydrogen, not all of which will be green, especially in the beginning. We expect to see a significant increase in electrolysis capacity beginning in 2030. By 2050, an additional 100 gigawatts may be required, where today there is very little dedicated capacity.

Both the increasing share of EAF and H2 electrolysis will significantly drive electricity demand, in particular for renewable energy.

Finally, scrap supply will have to increase significantly. This is especially true for China, where supply would have to double to as much as 400 million metric tons to accommodate a significant increase in EAF-based production. That would imply a jump in Chinese EAF production from 10% of the total to at least 40%.

As a result, the supply chains that today move large amounts of metallurgical coal and iron ore to steel producers will need to switch to providing equally voluminous amounts of electricity, hydrogen, scrap, and DRI/HBI. While eventually the aim will be for these new inputs to be “green,” initially there is unlikely to be enough production capacity to achieve that.

What does this mean for various regional economies? Here are some examples:

- Australia has several resources it could leverage, including renewable energy and natural gas, to become a leader in hydrogen production. Also has vast iron ore deposits that couldbe used to produce HBI for export, green steel products, or semi-finished products.

- Sweden already has ambitious plans to build green steel production leveraging its resources, which include carbon-free electricity and iron ore, to support domestic car production and other activities.

- Russia is aiming to use its gas for hydrogen and DRI production.

- Chinese steel producers want to start producing high-grade iron ores in regions such as Africa, in an effort to become more independent from Australian ore producers and make China's own steel production more efficient.

Trends to Anticipate

- German steel-producing group SHS and engineering firm Paul Wurth are exploring HBI production in Canada, combining Canadian high grade iron ores and renewable electricity from hydro power.

- BHP is collaborating with Chinese steel producer Baowu to support technology and other methods to reduce emissions. BHP also recently invested in startup Boston Metal, which aims to industrialize the molten electrolysis process.

- The Mining & Metals Blockchain Initiative is testing whether distributed ledger technology can be used to track embedded greenhouse gas emissions in supply chains. Members of the initiative include Anglo American, Glencore, Klöckner & Co, Tata Steel, and the World Economic Forum, among others.

- Brazilian Vale is collaborating with Kobe Steel and Mitsui to deliver low CO2 metallics to global markets.

- Swedish LKAB is collaborating with steel producer SSAB and Swedish energy firm Vattenfall to develop renewables and hydrogen capacity to replace coking coal by investing between $1 billion and $2 billion per year for up to 20 years. The first deliveries of the green steel will be going to car maker Volvo.

- Kawasaki Heavy Industries, J-Power, and Shell Japan are working with Australia’s AGL Energy & international partners to produce, liquify and ship hydrogen to Japan.

- Australian miner Fortescue plans to build Australia’s first green steel pilot plant and also aims to enter the renewable energy business at a large scale. It has announced several partnerships, including one with South Korean steelmaker Posco and South Korea’s Hyundai Motor Co, to collaborate on green hydrogen

The importance of renewable power, hydrogen, and scrap in these new value chains makes it vital and inevitable for energy, technology, engineering, and recycling players to become active in the transformation of the steel supply chain. That new competition will put pressure on incumbents in the mining and steel industries. Expect some jostling as players try to seize an early advantage in what will be a $1 trillion-plus transition over the next 30 years.

The large number of newcomers and the dramatically increased need to cooperate across industries to reduce carbon footprints will lead to a reevaluation of production locations and new contractual arrangements. It will also encourage the formation of new partnerships and symbiotic ecosystems to share the cost of the transition and develop new markets. One example is a memorandum of understanding signed between Rio Tinto and NipponSteel to jointly explore and develop low-carbon steel value chains. But many others exist.

The eventual greening of steel is inevitable, and the metallurgical coal business looks to be one of the biggest losers, with other technologies and commodities, such as renewable electricity and hydrogen, clear winners. Which will come out on top among regions and corporate players remains far less apparent. But given the amount of investment required and the length of time needed to bring products to market, the advantage will go to those willing to move quickly and take calculated and shared risk through partnerships to help create new industrial ecosystems and position themselves along the steel industry's value chains.