But digital technologies are transforming the after-sales business and squeezing profits. To mitigate the impact, manufacturers need to understand the threat to each branch of their after-sales business and develop counterstrategies.

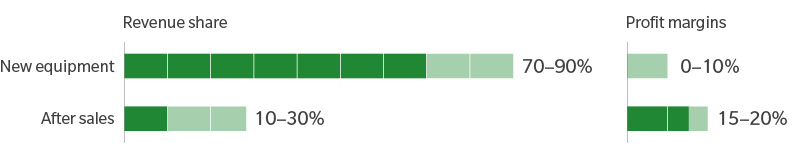

30% or more of a machine manufacturers profits typically depend on the after-sales business.

The pressure on after-sales revenue is a sobering reminder that digital technologies do not only have an upside potential. Eventually, digital opportunities will come through new business models, but few such new models have been implemented so far – and their contribution to profits has been marginal. Given that reality, manufacturers must play defense and focus on digital threats, which will not wait for new business models to take off. (See the Exhibit.)

Typical revenue shares and profit margins of German machinery companies

Source: Oliver Wyman analysis

Spare-Parts Sales Volumes Going Down

The challenges are clearest in spare parts, which often account for 80 percent or more of after-sales profits. Four digital developments are responsible for the pressure on the business.

First, condition monitoring will reduce the volume of spare parts needed. Traditionally, parts have been replaced after machine failure or at defined maintenance intervals based on age or length of use. Today, machines are equipped with sensors that provide early warning of a looming failure, such as vibrations that indicate a problem with a bearing, or else measure wear in a part, such as brake-disc thickness.

The result is a fall in demand for spare parts. Fixing a component before it causes the machine to break down often prevents greater damage, so a smaller-scale repair and fewer parts are needed. And, if worn parts are exchanged only when necessary, fewer are needed over the machine’s lifecycle.

Full-service contracts, based on condition-monitoring and remote maintenance, present a second digital risk to spare-parts profits. These contracts are gaining in popularity as users increasingly consider the total cost of purchasing and owning machinery. Wind turbines, for example, are often sold together with service contracts that cover 10 to 15 years of a turbine’s 20-year lifetime.

These contracts contribute to revenue if a manufacturer can charge enough for the service, and are a way to lock customers into consuming its spare parts. However, spare-parts profit suffers, as these parts are not sold separately at higher margins but instead are included in the contract. Moreover, full-service contracts are typically negotiated in the original sale of the equipment, and are exposed to the same kind of price pressure.

New Ways to Obtain Parts

The third digital development which threatens spare-parts profits is 3D printing. This lets other firms – contract manufacturers, spare-parts distributors, and even customers themselves – print spare parts for faster availability and to avoid expensive stocking of parts. Deutsche Bahn, for example, has started to print spare train parts, ranging from air grilles to headrests. It is planning to print more than 2,000 in 2017 and more than 15,000 in 2018.

3D printing services, such as Protiq, are expanding. Parcel-delivery service UPS has launched an on-demand manufacturing network that offers 3D printing services in select locations in the United States.

3D printing could be particularly relevant for proprietary parts with a design that is specific to a manufacturer. The customer will no longer be reliant on the manufacturer, reducing its pricing power and revenues. In a best-case scenario, the manufacturer will lose only the revenue from the sale of the part itself and may be able to recoup some of the value through its intellectual-property rights on the design. Third parties would need to pay to download the design in order to print it. However, if third parties can scan existing parts and then produce exact copies, then the manufacturer will lose this business entirely.

Online-trading platforms represent a fourth digital threat. They may increasingly fulfill users’ needs for catalog parts, – such as screws, drives, and sensors – which many customers have traditionally bought from the machine manufacturer out of convenience. Such digital platforms combine lower prices, price transparency, strong delivery service, and tailored integration with industrial procurement processes. For example, a customer can establish different internal buying roles with specific limits and approval procedures.

Established e-commerce companies, such as Amazon, Alibaba, and Mercateo, have set up online spare-parts platforms as they move into industrial services. Traditional spare-parts distributors, including Eriks, Zamro, and RSComponents, have set up e-branches, too.

Defending the Old, Embracing the New

To manage these risks, equipment manufacturers must understand their exposure, by analyzing their after-sales profit streams segment-by-segment. They should then prioritize high-risk areas and add a deeper level of analysis focused on customer behavior, competition, pricing dynamics, and exposure under different scenarios. By understanding their exposure, manufacturers can develop targeted defense strategies to prevent or delay the erosion of after-sales profits.

For example, manufacturers might mitigate the impact of online parts suppliers by using more proprietary parts. They could also offer convenient kits for repairs – a single box containing all necessary proprietary and catalogue parts. And they can expand their own online parts offering to match or beat independent online platforms by better tailoring it to the requirements of their respective customer groups.

Of course, digital technologies do not only create threats. They also present opportunities to improve operational efficiency and customer service. Machine manufacturers could design smart-service contracts that become a basis for upselling and the creation of additional value. For instance, performance contract pricing can be based on a machine’s in-service time. Manufacturers can also provide tips on machine optimization and software updates for additional fees. A well-designed full-service contract with variable pricing based on performance parameters could even be more lucrative than selling spare parts to that same customer.

Rolling out such innovative solutions will require changes in the mindset and behavior of manufacturers and customers. These transformations will take time – more time than for some of the digital risks to unfold and eat into profits. But if machine manufacturers do not implement such changes in the long run, they will have to base their profit models on new equipment rather than after-sales contributions – or will have to accept lower profitability. But regardless of this longer-term challenge, manufacturers today depend on after-sales profits, which are driven by spare-parts sales. The short-term priority is clear: Protect the current business.

About Authors

Wolfgang Krenz is a Munich-based partner in Oliver Wyman’s Automotive and Manufacturing Industries practice and focused on strategy innovation, organization and large scale transformation for machinery manufacturers. Wolfgang Weger is a Munich-based partner in Oliver Wyman’s Automotive and Manufacturing Industries practice and an expert for growth strategies, commercial effectiveness, and pricing.