Machinery manufacturers now must deal with the digitally spurred challenges of quality management, integration of ecosystem partners, and systems reliability to position themselves ahead of the competition.

Traditionally, manufacturing machine makers kept a tight rein on their individual products and the value created by them. But digitalization is now changing all that. As production machines become integrated seamlessly into supply chains, clients are looking for greater insight into operational data and the ability to take active control of their machines and production centers.

One outcome of this process has been greater collaboration between equipment/machine systems providers, machine manufacturers, and component suppliers in terms of systems integration and risk sharing. But along with digitalization and integration comes a hidden cost: Machine makers will need to deepen their understanding of functional and operational constraints across the entire value chain. Only then will they be able to offer customers the higher levels of quality, reliability, and flexibility they are seeking.

30% of 30 surveyed German manufacturers provide proprietary cloud services.

The benefits of transparency

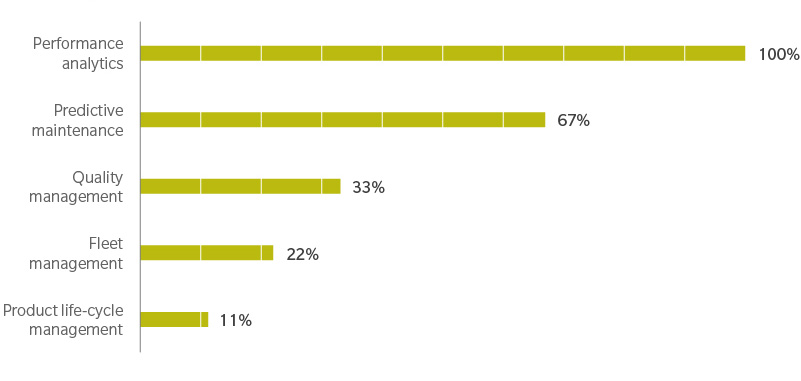

A major benefit of digitalization is the ability to analyze and optimize machine performance in real time, using data generated by embedded sensors or cyber-physical systems that is then fed into industry clouds. (See The Exhibits.) Leveraging this production data can lead to significant performance and cost improvements: Real-time monitoring of the latest networked paper manufacturing machines, for example, minimizes energy and material waste. It also avoids unplanned downtime as third parties can provide targeted offers for auxiliaries, spare parts, and maintenance services.

Cloud offerings of 30 German manufacturers

Source: Oliver Wyman analysis of manufacturer cloud service offerings

Use cases of proprietary cloud offerings for machine manufacturers

Source: Oliver Wyman analysis of proprietary manufacturer cloud service offerings

The enhanced transparency of manufacturing systems and their operations will enable customers to see new potential improvements and act immediately. Instead of being content with a normal bottling machine, for example, a beverage maker might instead require that the machine be designed to continuously optimize its own operation and be adaptable for instantaneous changes, such as handling the latest on-trend bottle designs.

While this may be ideal from a customer perspective, it will put unprecedented pressure on machinery manufacturers to better understand the entire manufacturing system within which the machinery operates, from technical constraints to functional behavior and performance boundaries.

Digital Challenges for Quality and Reliability

Digitalization will enhance machinery manufacturers’ ability to visualize their own supply chains, enabling them to improve transparency into component suppliers and thus the quality of their machines. Such close working partnerships will be especially important as machinery manufacturers’ clients demand ongoing enhancements tailored to their production activities.

Manufacturers are likely to see a rise in quality and reliability concerns, as an increasing number of interfaces between system components and value chain partners introduce greater variation in the component structures of machines. Machine manufacturers will have to be attuned to relationships, interactions, and potential gaps in transparency to determine how the quality and reliability of its machines within a production system might be impacted. And turn this information will need to feed into performance optimization data.

Reliability engineering and testing will need to be designed and executed with a functional orientation – going beyond the boundaries of individual component groups to cover the scope of an entire system. Advanced risk management will be used to qualify and quantify high-risk areas and prioritize the most critical areas for review.

A view to new business models

By taking an integrated, responsive approach to quality, reliability, and risk management, manufacturers can generate more value for customers in refining machine and production system performance, which in turn could lead to new business models. In aerospace, for example, airlines are switching to usage-based pricing models for engines, paying a fee to the manufacturer for each takeoff and landing, rather than buying the engines outright. Machine manufacturers could move from selling one-off machines, to generating ongoing revenue based on machinery uptime and other key performance indicators. So, for example, a client that wants to use automated welding equipment might pay per successful welding point rather than buying an automated weld line.

Machinery manufacturers also could increasingly take on the role of systems integrators, managing a downstream supply chain that is seamlessly integrated with and responsive to changing real-time customer needs. Doing so would require adopting advanced analytics and artificial intelligence to build advanced models and simulations, but could result in powerful new sources of value.

In sum, technology developments like cloud computing and the Internet of Things are quickly moving beyond consumer-facing products to envelop the entire production value chain. Machine makers may find this new level of integration and digitalization challenging, but keeping pace with the functional and operational evolution of production systems will be critical to meeting their customers’ digitally enhanced needs for seamless, transparent, and real-time information and adaptability.

About Author

Richard Hell is a Munich-based Partner in Oliver Wyman’s Harbour Advanced Manufacturing and Engineering practice and focused on operational improvement, technical risk and quality management as well as digital manufacturing.