By David Kaufmann, David Kaufmann, and Mark Kiel

Traditional approaches toward reducing the costs of technical products are reaching their limits, at a time when cost efficiency is becoming increasingly critical. To achieve today’s targets, a step change in thinking is required, one that takes a fresh look at cost. Companies need to adopt new product cost-down approaches, methods that take a multidimensional view of cost and examine its sources.

Uncertainty surrounding demand and supply is an inescapable condition – and one that is growing. Industries far and wide – from manufacturing to consumer goods, from automotive to telecommunications – are all talking about becoming recession-proof. The desire is to generate free-cash flows and profitability buffers to ensure they can weather whatever the market throws at them. For example, automotive original equipment manufacturers (OEMs) are spending hundreds of billions of dollars on e-mobility transformation over the next five to ten years. That level of investment is not sustainable without fundamentally rethinking how additional efficiencies can be achieved.

After decades of small, incremental improvements, the line of attack is to re-evaluate cost structures to identify step changes in efficiency. The search is on for big wins.

10-20% total product cost reduction potential using a next-generation product cost-down approach

REACHING THE LIMITS OF PREVIOUS APPROACHES

While some industries are more advanced in cost-reduction methodologies than others, addressing product cost in-depth is a sensitive topic. Companies rightly fear that changes to their products could potentially lead to poor customer reception, thus lowering sales. Past experiences with cost reduction have also left a mark, reinforcing the belief that reducing product costs is a complex and slow business.

The hard truth is that customer product perceptions have little or nothing to do with inherent product cost. Substantial reductions can be achieved by redesigning products to focus on the features that are highly valued by customers, while removing unnecessary complexity and rarely used functionality. This can result in a 10-20 percent reduction of total costs. All too often, companies have treated product cost reduction primarily as a procurement-focused exercise. Using commercial tools such as structured market tests, costs are reduced either through lifecycle cost-reduction schedules agreed upon by suppliers or through onetime supply-base restructurings.

Even where companies have looked at engineering and design-cost reduction levers, these have largely been used in just a few key product areas. Rarely have companies taken a holistic view of their products, identifying opportunities and cost-reduction impacts across functionalities and product areas.

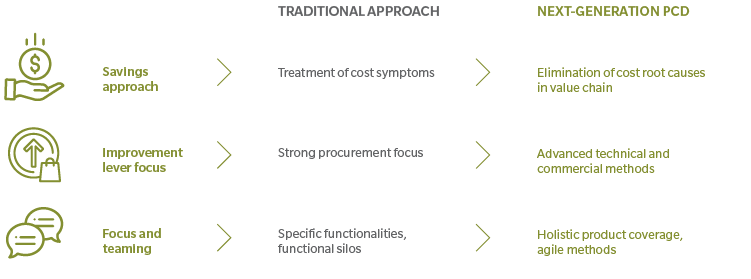

Exhibit 1: Next-generation product cost-down

Source: Oliver Wyman analysis

HOW NEXT-GENERATION APPROACHES DIFFER

Unlike other approaches, the reductions achieved through next-generation approaches are sustainable over the longer term due to the holistic view that encompasses all aspects of the product, from design to manufacture and sales, ensuring that there are no hidden and unforeseen consequences. (See Exhibit 1.) Just as important, the approach tackles the underlying non-optimized elements of the operating model and organization that have led to higher cost levels. For example, an international plant-engineering firm discovered an excessive safety buffer in one of their electric motors.

Rather than simply removing the specific buffer, the team traced the issue back to its root cause, which turned out to be an outdated performance guideline introduced years before. Identifying the underlying issue allowed the company to sustainably reduce the cost for the entire product series, rather than optimizing only the specific model.

The second aspect differentiating a next-generation tactic from a purely procurement-focused approach is in how it leverages technical expertise to drive deep into the design and production process. Engineering and design experts work side-by-side with internal experts to challenge existing thinking. The internal experts involved in the process are drawn from multiple sites and/or product lines. Their presence stimulates a robust approach to internal benchmarking, complementing that of the external challenge. This combination of internal and external expertise ensures rigorous testing of existing as well as new designs and specifications. Doing so provides them with a trump card in negotiations, as they no longer have to rely on suppliers for technical input.

The third aspect differentiating a next-generation methodology from traditional approaches is that it relies on agile methods to ensure holistic coverage of the product as a whole, rather than focusing on individual aspects of functionality. The agile approach uses clusters of experts to address the two dimensions of root causes (or “cost topics”) and product functionalities. By rotating through the different combinations of topics and functionalities, this approach ensures that the various perspectives, as well as downstream and upstream consequences, are considered when developing new cost-reduction ideas. The ideas are then validated and refined in multiple sprints in the drive towards an implementation-ready business case, with first results placed on the table within weeks of the start date.

SEIZING THE OPPORTUNITY

These next-generation approaches represent a major opportunity for companies to unlock step-changes in efficiency. To turn it into a success story, companies need to embrace a new mindset that fundamentally challenges the status quo across the value chain. This requires full and continuous leadership involvement and a clear communication of the new paradigm.

Companies need to treat product cost reduction as a proactive opportunity rather than a reactive tool, well before any crisis arises. Additionally, manufacturers should combine quick wins that result in rapid profitability improvements with longer-term measures to create compelling success stories. These efforts inspire the organization and unlock short-term cash to fund more transformative levers. Involving customers and suppliers in the product cost-reduction efforts represents another success factor to develop win-win opportunities for all stakeholders. Furthermore, it is essential to integrate the methodology and learnings from these new approaches into the organization so they become an inherent part of the company’s cost management approach.

Whether a company is facing a major industry disruption or economic volatility, revisiting the core tenets of their cost structure and value chain should be a key priority on any executive agenda. The next level of product cost optimization lies within reach for any company that seizes the opportunity.