This article first appeared in on Forbes July 10.

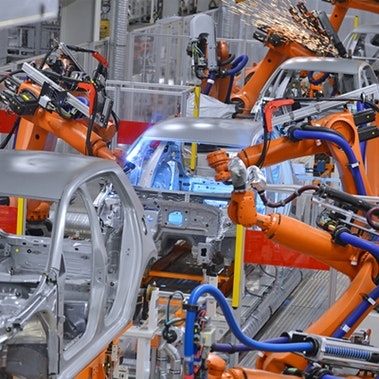

Manufacturing executives in the United States and other developed economies – whether involved in the production of automobiles, aircraft, trucks, or combines – agree: The single biggest threat to their operations over the next decade is a shortage of labor. The reason behind the gap relates to demographics; an oversized generation – baby boomers – is starting to retire, and not enough of the next three generations are interested in taking their place.

Most people think this deficit is concentrated in skilled labor categories, and there is no doubt that finding candidates with the right training for certain jobs is part of the problem. But the shortfall is affecting many employment categories – skilled and unskilled labor. Rather than a skills gap, the manufacturing world is facing a numbers gap – literally there aren’t enough eligible candidates applying for most job openings.

This means any solution aimed at shrinking the gap must go beyond offers of more training and focus on retention as much as recruiting. Companies must figuratively begin to build a “moat” around the current workforce, making it difficult for other employers to lure workers away with more attractive compensation offers. Retention is just as important as recruitment, given the cost of hiring and training a new worker, which can run anywhere from $500 to $5,000 per worker – a number which does not include the negative impact to quality and efficiency from the incorporation of new workers who are less familiar with the product and processes.

Cost of hiring and training a new worker can run anywhere from $500 to $5,000 per worker.

COMPETITION FOR WORKERS

A necessary step in making manufacturing jobs more attractive and building that protective barrier around your workforce is recognizing that the competition for dependable employees is fierce. Rivals include growing sectors, such as technology and healthcare, that are currently less prone to layoffs than manufacturing has been. Job security may not be something manufacturers can promise, so they need to be more creative.

Automakers and other manufacturers are also battling a rising rate of absenteeism, with some plants reaching as high as 20 percent. (See Exhibit 1.) That means that employers must look for candidates willing to both accept jobs and show up every day. Add to all that, the reality of a record-low 3.8 percent unemployment rate, and manufacturers can begin to appreciate the daunting nature of their challenge.

So where to begin? Automakers and other manufacturers can look to some of the same strategies their engineers and marketing and sales departments use to design and sell products: Find pain points and design products that help prospective customers fix them.

Exhibit 1: Why The Automotive Industry Has To Keep Looking For New Workers

The Rate of Employee Turnover in Durable Goods, Including Autos, Significantly Outpaces Other Industries

DESIGN-THINKING IN HR

Human capital departments should consider this same kind of design-thinking approach, which involves creating different personas – in this case, of their workers – and mapping their journeys. Employers can set themselves apart from rivals by mapping these journeys beyond the walls of factories and into their employees’ homes, providing ways to reduce both the complications and stress in their lives.

To do this effectively, human capital must recognize what drives employees when looking for, accepting, and changing jobs. There are basic minimums – the “must haves” – which include competitive wages and benefits. But there are other factors that involve lifestyle and convenience, and building that moat starts with taking a more empathetic approach to workers on the assembly line who sometimes feel like they’re treated like the robots they fear will replace them one day.

Offering perks and services is something we see more often with the treatment of professionals, but today it is a strategy widely used by tech companies to entice prospective employees and then build a moat around them. In addition to a paycheck and benefits, tech companies acknowledge that employees value flexibility in scheduling; being offered healthy, free or inexpensive meals so they do not have to leave the work site; and free or discounted transportation solutions to commuting headaches. These kinds of perks make leaving companies harder because it means those pains would return in the next job.

WHITE-COLLAR PERKS

The result of this exercise is a more individualized understanding of the workforce and what they go through each day. For example, maybe the most stressful part of the day is leaving work, picking up children and trying to cobble something together for dinner. If the factory offered pre-portioned meal kits to pick up on the way out the door, they just helped the employee’s life be a little easier and, perhaps, healthier. “How can I live without this?”, an employee may think if approached by another company to change jobs.

But family responsibilities also bring with it other headaches. Consider on-site emergency daycare or urgent care to help employees handle problems without missing a full day of work. One audacious solution could be to issue smartphones for everyone as a method to roll out company policy, handle absenteeism, scan quick-response QR codes for training modules, share rides to the plant, and learn about daily work schedules or corporate announcements. It may seem extravagant, but for workers who do not normally get such perks it may be a deal-clincher.

These solutions no doubt come with a price tag – and one some manufacturers may think short-term is not worth it, hoping the problem will go away. But they need to remember – the status-quo is not a cost-free option either.