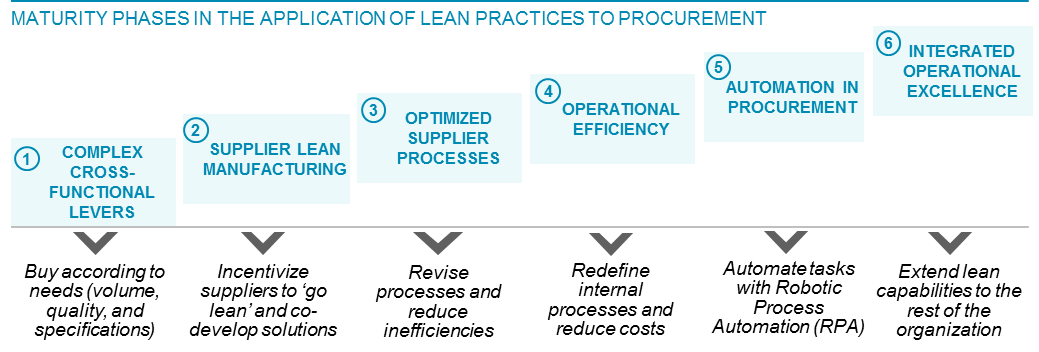

They all share certain key aims, such as cutting inefficiencies (“mudas” in Japanese) and unnecessary spending, keeping to deadlines, and monitoring for quality. The different approaches attend to these elements as they pertain, not only to procurement functions, but also the company more generally and its relationship to suppliers. But how should the procurement function go about putting these methods to work? And are there limitations to each approach?

One in five Chief Procurement Officers report having implemented continuous improvement methods of one kind or another; most, however, are unfamiliar with the process of applying these same methods across the procurement function.

To develop a lean mindset in procurement, organizations must align the function with broader, company-wide strategies

Industrial direct procurement – or more broadly production procurement – seems to be the furthest along in applying methods of continuous improvement to their activities: Because of their close proximity to manufacturing, win-win supplier productivity initiatives are being undertaken everywhere. However, it is a simpler task to transform the production processes of a small or midsize company than it is to change the production processes of a giant firm like Apple or Solvay.

Which continuous improvement methods are best suited to procurement (including non-industrial procurement), and how will these methods help procurement realize their goals?

How to characterize lean procurement?

Let us first review some of the approaches firms take to continually improve their businesses. “Kaizen” is the most generic, as implied by the name which literally means “positive change” in German. Six Sigma addresses quality issues by reducing variability in production processes. Lastly, the “lean” school aims to optimize productivity by limiting waste of all kinds.

Waste in production processes takes seven general forms:

- Overproduction: Engaging with suppliers at inadequate levels of granularity leading to redundancy.

- Wait time: Administration time for creation of supplier accounts in duplicate ERPs.

- Inefficient transport: Sub-optimal freight loads coming from suppliers.

- Useless stock: Over-commitment on volumes for obsolete goods.

- Over-quality: Contracts covering goods or services never used or redeemed.

- Inefficient processes: Fragmented information systems (IS), and remoteness of internal clients.

- Redundancy: Reworking erroneous data from IS (nomenclature, suppliers).

The lean approach to procurement would thus include both “natural” levers resulting in lower prices, and more sophisticated levers addressing the Total Cost of Ownership (TCO) and the cost of the function itself.

Key factors to successful lean procurement

To develop a lean mindset in procurement, organizations must align the function with broader, company-wide strategies. From there, it is also essential to understand the objectives and expectations of different operation lines in order to mobilize the organization as a whole in securing the successful execution of improvement methods.

Once this has been done, the next steps consist of embedding the principles of “leanness” in procurement’s activities by:

- SEGMENTING the different functions associated with procurement: supply, procurement administration, tactical purchasing, and strategic purchasing. Lean approaches are particularly efficient for downstream activities like ordering/requisitioning and more specifically and can brilliantly streamline Third Party Risk Management activities and reduce related internal and external fatigue

- FOCUSING resources on more value-adding activities. Some procurement functions have deployed (or started to explore) RPA to automate the repetitive and manual tasks of buyers, allowing them to focus on upstream phases of the purchasing process, where the greatest value is created (for example, designing commercial offerings, defining specifications, and engineering target prices)

- DIFFERENTIATING the procurement process (from the formulation of needs through the payment of suppliers) to adapt it to a company’s strategic and financial stakes – for instance, by adjusting the sourcing process depending on the type of products involved: from essential and risky, to commodities or productive investments.

- TRAINING buyers to use Six Sigma and other methodological tools (DMAIC, 5S, VSM, etc.). Procurement functions can either train the entire procurement group (and use certifications signifying different levels of training), or create expert units with the mandate to lead large, cross-divisional projects.

- MOTIVATING all parties subject to these changes with attractive incentive systems, either to run “kaizen blitz” projects (to which the parties would actively dedicate time) or to encourage the implementation of new, directed solutions.

- TOOLING the procurement function with efficient information systems will allow for simple data access, above all in the Smart Analytics era. As a result, processing times will be kept to a minimum (such as supplier auto-registration internet portals) and these systems will structure the broader procurement process (such as e-procurement).

It’s a ‘one step at a time’ philosophy, it is iterative and is conducted mostly through short, very focused projects around targeted problematics in order not to dilute energies and achieve tangible results in two to three months

Lean procurement, where to draw the line?

The challenge of applying the principles of leanness to procurement is proportional to an organization’s capacity to merge these principles into its DNA. There is, however, a subtle line to draw between doing things by the book and truly grasping the essence of the lean method:

- Emphasizing standardization and reducing the variability of processes can generate complexity, resulting in lost problem-solving agility, especially when dealing with suppliers;

- Specialization of teams tends to create experts who then struggle to grow within an organization, both inside the procurement function, as well as in other departments;

- Rationalization of supplier production costs at the expense of other activities such as R&D and innovation weaken relationships with suppliers;

- Automation in procurement can be a burden if processes and systems are not aligned – it may not be suitable for every organization;

- Obsessive pursuit of savings can damage the procurement function’s reputation and positioning within a company.

The lean approach adapts procurement to a company’s core strategy, whether that is based around costs, quality, and/or growth. Embedding lean methods across your organizational DNA – while adhering to a disciplined set of guiding principles and avoiding common pitfalls – will enable procurement to fully realize cost management objectives. Effectively, setting the foundation for leanness to become procurement’s guiding principle for productivity.