Many supply chains face challenges that have significant implications in terms of cost, speed, and (product) quality. In our experience, the most critical supply chain challenges—despite years of efforts and often significant investments—are lack of transparency due to inconsistent or even unavailable data, high proportion of manual (paper) work, lack of interoperability, and limited information on the product’s lifecycle or transport history. In many cases, blockchain applications can counter these inefficiencies and add new value.

Blockchain was first deployed commercially about four years ago in the financial-services industry to make trade/claims settlements and international payments more secure and efficient. More recently, other industries, including retail and consumer goods, are piloting blockchain applications. By leveraging the technology’s decentralized cloud database, which records data in non-changeable blocks that can be shared with any number of players, global players like Walmart or Carrefour intend to increase transparency and drive value at every step of the supply chain.

End-to-End Data Transparency

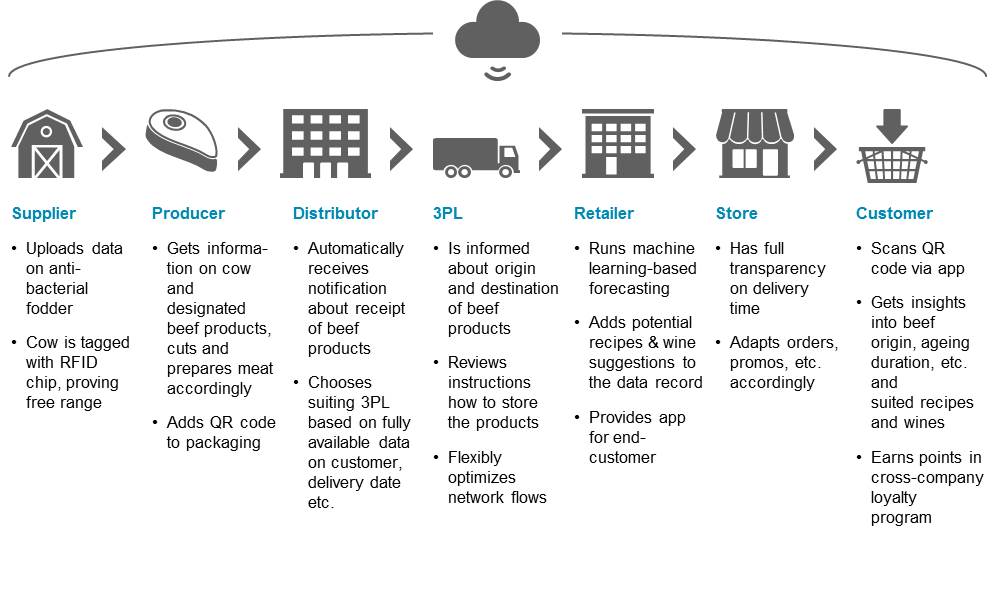

End-To-End Blockchain-Enabled Supply ChainExample Of Dry Aged Beef

Taking the supply chain of dry aged beef as an example, the significant potential of blockchain along the whole supply chain quickly becomes apparent (see “End-to-End Blockchain-Enabled Supply Chain”). In response to customers’ increasing demand for local and organic products with clear origin, for example, retailers could provide selected product-related data through an app. With a simple QR-code scan on their smartphone, customers could validate every step the beef has taken through the supply chain, and match that journey against their expectations. Any kind of historical as well as real-time data on the beef product, be it related to the origin (such as feed or breeding), timing (such as aging duration, time in transport, best before date), location (of the farm and of the beef throughout the supply chain) or additional information (such as recipes and wine suggestions) is continuously available from the blockchain database in a single, consistent version (“one source of truth”). Through further value-added services like specific recipes and wine suggestions, retailers can drive sales of other products.

Of course, blockchain can be used in supply chains of industries beyond retail. In the spare-parts industry, for example, blockchain could capture and record spare-parts details along the full lifecycle, including remanufacturing. Numerous use cases are also conceivable in the logistics industry, such as fully digital freight papers, a digital proof of transfer of liability for goods, or automated customs clearing. Indeed, shipping-giant Maersk announced earlier this year that it is collaborating with IBM to develop blockchain applications for freight tracking and administration, including customs, in an effort to increase transparency, decrease idle time, and reduce cost.

Blockchain Is the Backbone of Supply Chain Digitization

Blockchain is more than a pure electronic data interchange (EDI) – it is the backbone of digital supply chains, offering distinct advantages over today’s conventional supply chain IT infrastructure and analytics capabilities.

Blockchain is scalable—any number of players may be seamlessly integrated into the blockchain without losing data consistency. Blockchain is independent of adjacent and legacy systems, making implementation quick. Once data is recorded in a block, it is non-changeable, and the distributed-storage feature makes cyber attacks very difficult. Every player along the chain holds a complete copy of the data. But, by defining specific access rights, players can ensure that confidential corporate information is kept private. Retailers, for instance, can restrict the data customers may access to just the beef product, instead of letting them view irrelevant information on the upstream supply chain. The vast amount of available, consistent data is a powerful base for advanced analytics, like machine learning-based forecasting. Finally, a shared database means less administrative work, which lowers transaction costs and improves efficiency.

Keys to Successful Integration

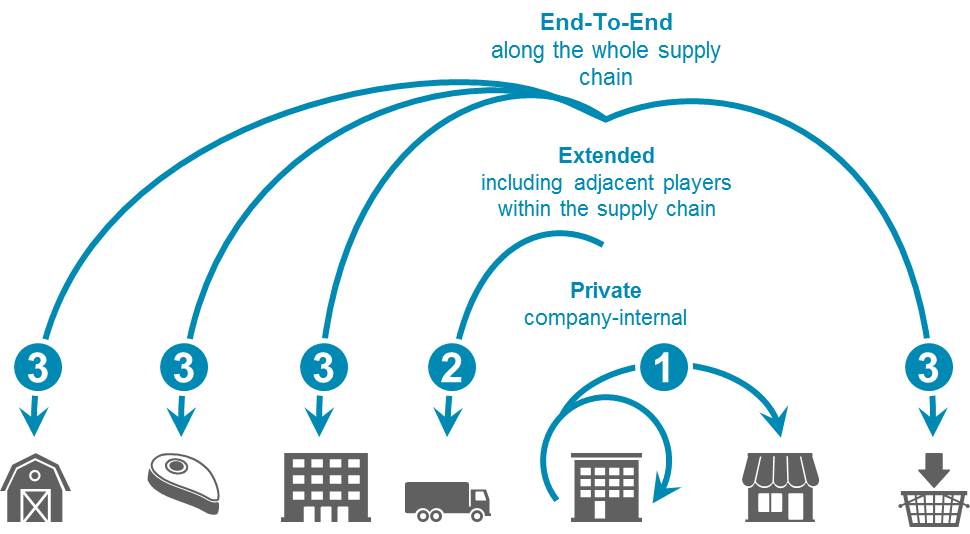

In our experience, a three-step approach to gradually integrate blockchain into supply chains is most likely to be successful (see “Stepwise Blockchain Integration into the Supply Chain”). To start, a company-internal blockchain should be set up, giving the organization time to get accustomed to the technology, while insuring data availability and consistency. Next, extend the blockchain to adjacent players, such as third-party logistics and direct suppliers, fostering data exchange. Finally, integrate all players along the supply chain, including the end customers, to the blockchain.

At its full potential, blockchain improves the customer experience, drives value end-to-end, and roots out inefficiencies, thereby lowering costs.

Stepwise Blockchain Integration Into The Supply ChainThree-Step Approach